OEM/ODM Service

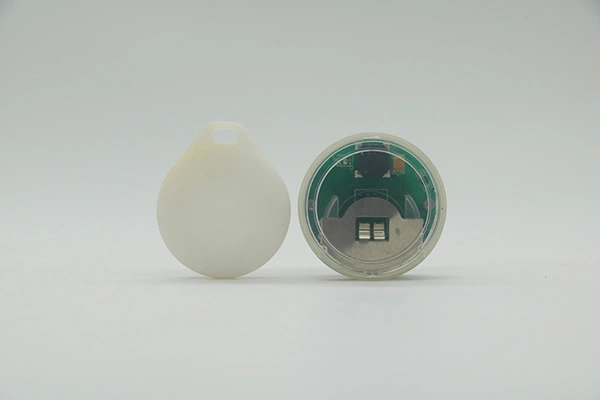

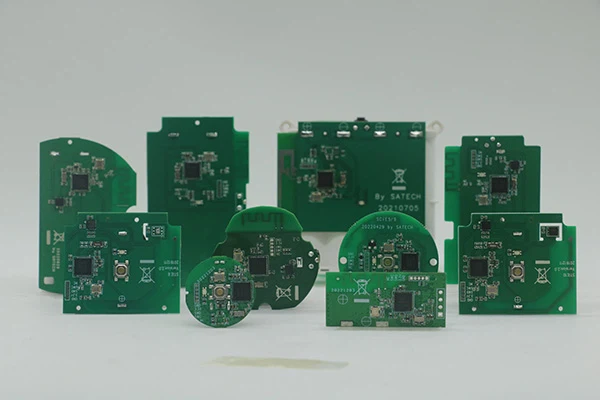

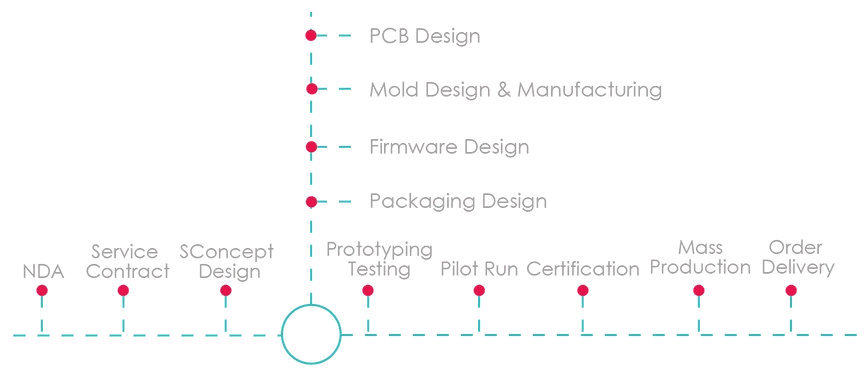

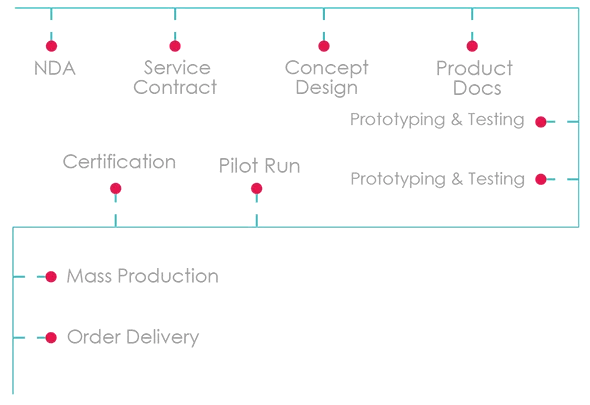

As a forerunner in the field of researching & developing BLE beacons/tags (with sensors) in China, we have accumulated rich experience in the hardware design, development and manufacturing, so we are glad to take part in helping any one who is working in the field with one-stop OEM/ODM service solution.

Original Equipment Manufacturing

An OEM product is made according to the buyer’s product specification. For example, any product with a customized design, material, dimensions, functionality, or even colors can be classified as OEM.

Product specification examples

- CAD files

- Design drawings

- Bill of materials

- Color chart

- Size chart

Original Design Manufacturing

An ODM product is based on an existing design – to some extent developed by the manufacturer rather than the buyer. An ODM product can either be the result of the supplier’s own product development efforts – or a replica of another product that’s already on the market.

To help you understand the difference between them better

| Factor | OEM | ODM |

|---|---|---|

| Unit price | No difference | No difference |

| Injection molds and tooling | Paid for by the buyer | Paid for by the supplier |

| Product development time | 2 to 6 months | 1 to 4 weeks |

| Production time | No difference | No difference |

| Product spec sheet | Provided by the buyer | ‘Reverse engineered’ by the buyer or provided by the supplier |

| Product compliance | No difference | No difference |

| Intellectual Property Ownership | IP can be owned by the buyer | IP owned by the supplier or another importer |

| Benefits | 1. The suppliers are at their core OEMs. Often less hassle to buy OEM products. 2. You can freely customize the product (within what is technically possible to make) 3. You own the IP (as long as you protect it) |

1. Shorter product development cycle 2. Many ODM products can be customized to a certain degree 3. You don’t need to pay for the tooling |

| Disadvantages | 1. You pay for the tooling 2. It can take months to create new tooling |

1. Limited product selection (you get what the supplier can offer, which may only be a fraction of their list products) 2. It is time-consuming and complicated to reverse engineer a specification. It can often take more time than to design an OEM product from scratch 3. Many other companies are already selling the same product, or they will in the near future. 4. You don’t own the IP of the product, and may even end up on the wrong side of an IP dispute. |